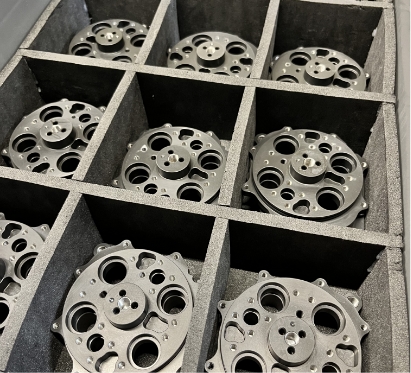

Using state-of-the-art technology and a team of highly skilled engineers, we are proud to produce precision parts for some of the most prestigious businesses in the world.

Our UK base is a state-of-the-art, 9625 square foot facility, including an extra 3203 square foot mezzanine area. We use the latest in CNC machining technology including 4 and 5 axis machines and mill/turn lathes. we operate 28 machining centres, including 10 CNC Hurco® vertical mills and 8 CNC lathes combined with the latest solid modelling CAD/CAM capability and CNC inspection facilities. We operate a 24-hour double shift system, reducing lead times whilst maintaining the highest level of quality.