Our Approach

Our Approach

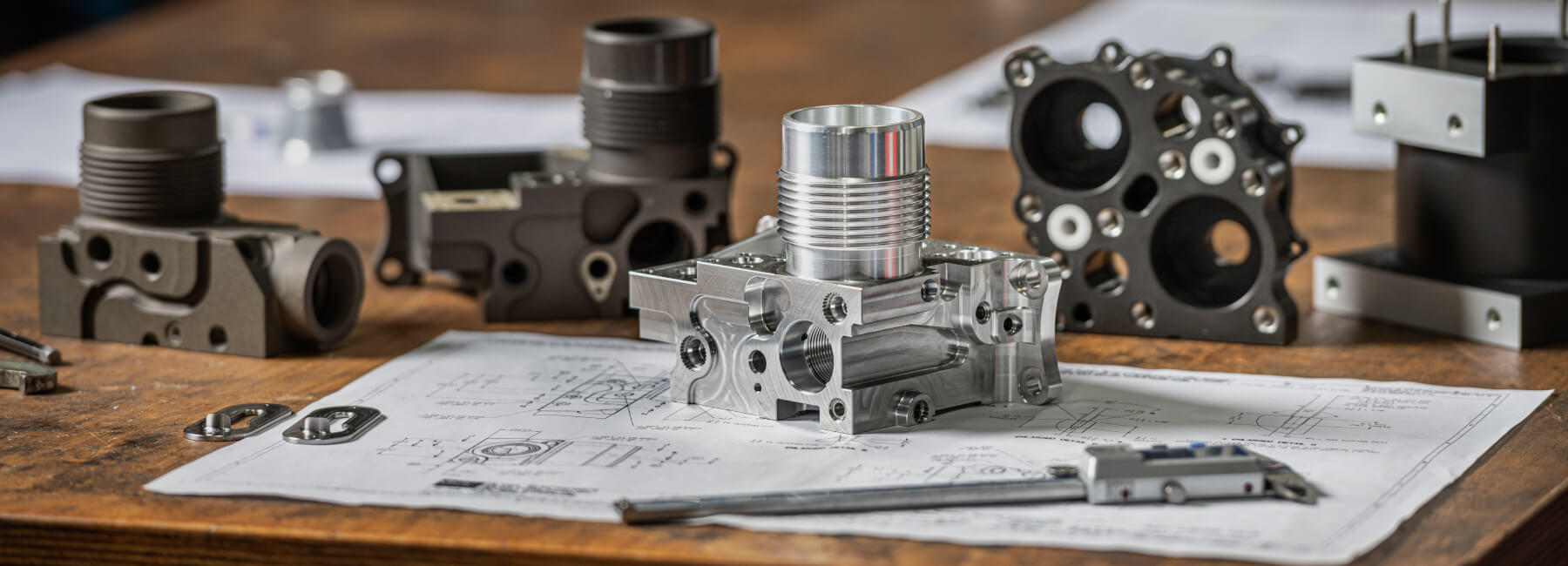

We run the complete suite of Prodman 9000, a system specifically designed inline with the ISO (International Standards Organisation) 9000 standard.

Prodman is a complete production management suite designed for the needs of small to medium sized manufacturing enterprises or subcontractors with assembly operations. The software suite contains all that is required to computerise and control all aspects of a business and puts that information at your fingertips. This include; Sales Order Processing, Works Order Processing, Stock and Inventory control, MRP, Manufacturing Route Card, Bill of Materials (BOM), Job Costing, Scheduling, Capacity loading / Capacity planning, Shop Floor Documentation and Certificates of Conformity.

This allows us to control every aspect of our production process from quotation through material stock control, scheduling, production, delivery and invoicing.

Managing and fulfilling customer orders. It involves a series of steps from receiving the initial order to shipping the product to the customer.

Managing and optimising the stock levels of products and materials in our inventory. It involves a series of activities aimed at ensuring that the right quantities of the right products are available at the right time and at the right cost.

This can include a wide range of documents that provide information about the production process, such as work instructions, quality control documents, test results, and production reports.

These are documents that certify that our products meet the required regulatory or industry standards. They are issued by certification bodies and provide assurance that the product is safe, reliable, and meets the specified performance requirements.

Because we standardise on the Hurco machining platforms in conjunction with the Prodman 9000 system we can accurately schedule machine capacity planning up to 12 months in advance, perfect for customers that require annual call off schedules or staggered orders.