What We Do

What We Do

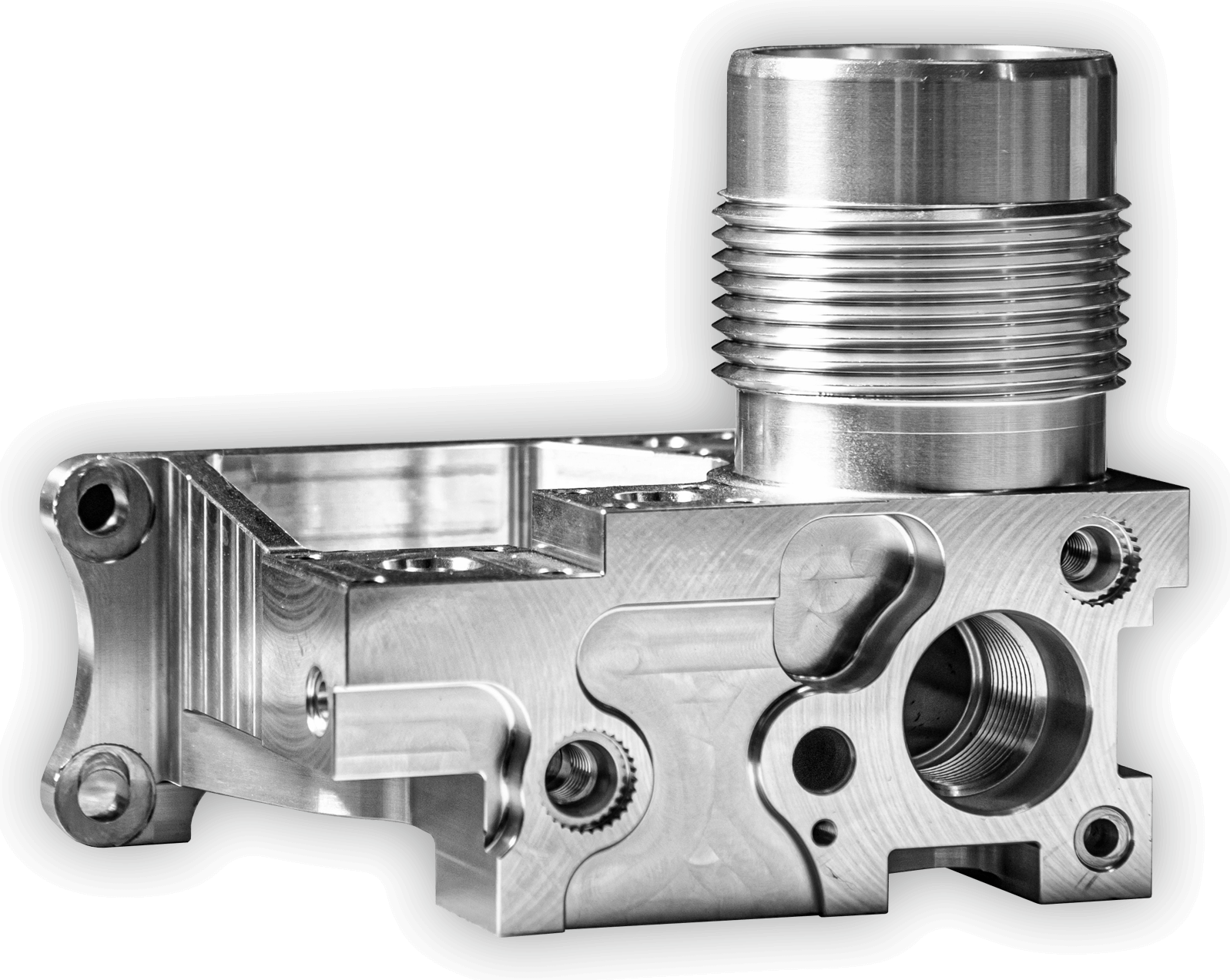

We offer a range of specialist, precision engineering services including conventional milling, jig boring and electrical discharge machining.

We operate 3 Bridgeport BRJ vertical turret mills ideal for light materials such as aluminium, copper and brass as well as specialist machining requirements.

This offers greater accuracy on larger bores we maintain two vertical jig borers for precision work. Our boring traverse capacity is upto 400mm (x), 300mm (y) and 600mm (z) and are ideal for machining precision shafts.

We offer CNC spark erosion upto 18" (x), 13" (y) and 6" (z). Spark erosion is ideal for toolmaking and machining of hardened materials.

Our surface grinding section is equipped with 3 Jones & Shipman machines with upto 457mm X 152mm reciprocating tables and are suited to finishing hardened materials.

Our precision engineering services involve the use of advanced technologies and techniques to create parts and products that are extremely precise, often with tolerances measured in microns or even nanometers. The ultimate goal of precision engineering is to create parts and products that are not only highly accurate but also reliable and durable.

Achieving this requires a combination of technical expertise, advanced equipment, and a deep understanding of the specific requirements and challenges of each application. Our range of complementary precision engineering services as detailed above.

The result is a product engineered with precision and to the highest standards expected by our clients, representing our engineering excellence and first-class service. Each product is quality assured which is certified.

Using state-of-the-art technology and a team of highly skilled engineers, we are proud to produce precision parts for some of the most prestigious businesses in the world.