What We Do

What We Do

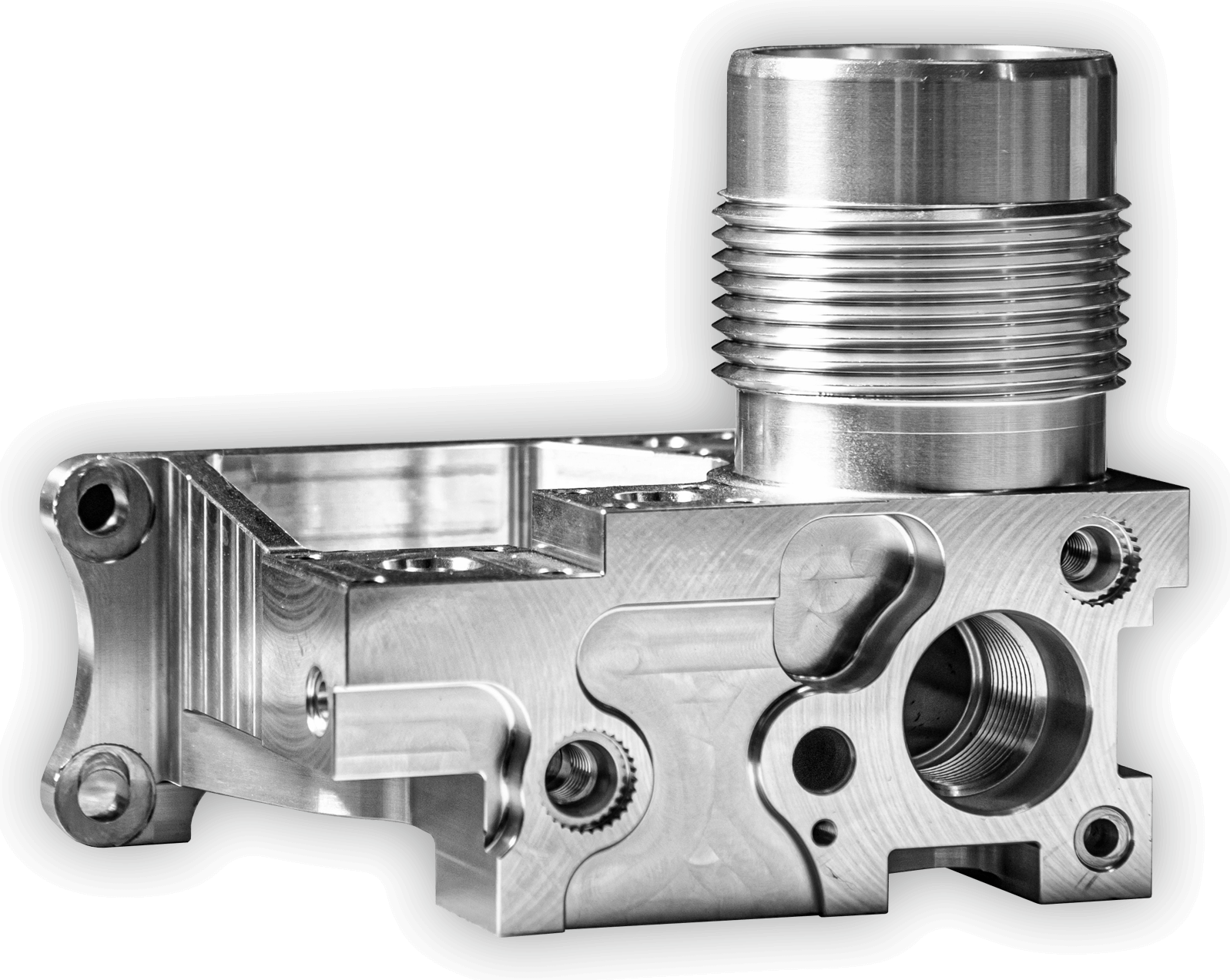

We operate 3 CNC milling centres with 4-axis capability. 4-axis milling allows machining of curved and complex profiles with fewer set up changes.

A CAD drawing is first exported into a compatible format and converted into machine instructions using the hyperMILL® CAM software.

The CNC machine needs to be calibrated to ensure that the material is properly aligned and at the correct height before the execution can start.

The CNC machine is then activated and the cutting tool is guided along the programmed path to remove raw material from the component.

Throughout the machining process, sensors and precision measurement tools are used to monitor the dimensions and quality of the part.

4-axis milling is the same as a standard 3-axis mill, but the 4th axis allows the cutting tool to move along a rotating workpiece. The benefits are greater with even more part processing options and more detailed engineering, which is faster and more accurate. This is particularly beneficial for prototypes and custom machining. We operate 3 CNC milling centres with 4 axis capability, 2 vertical and one horizontal.

The horizontal Niigata® SPN-50 machine offers high production rates with its twin horizontal rotating pallets and spindle speeds of 50-12,000 RPM, helical interpolation (thread milling), a table probe, tool breakage detector and automatic tool length measurement & offset. This machine is used for high volume production of small components.

For our vertical milling, we use both Hurco® BMC 3017 and Hurco® 30 HT/M which machine complex surfaces and areas otherwise unreachable on 3 axis machines, including pockets and holes to be cut around a cylindrical part. This also allows for the machining of conventional components on 4 faces within one operation.

The result is a product engineered with precision and to the highest standards expected by our clients, representing our engineering excellence and first-class service. Each product is quality assured which is certified.

Using state-of-the-art technology and a team of highly skilled engineers, we are proud to produce precision parts for some of the most prestigious businesses in the world.