What We Do

What We Do

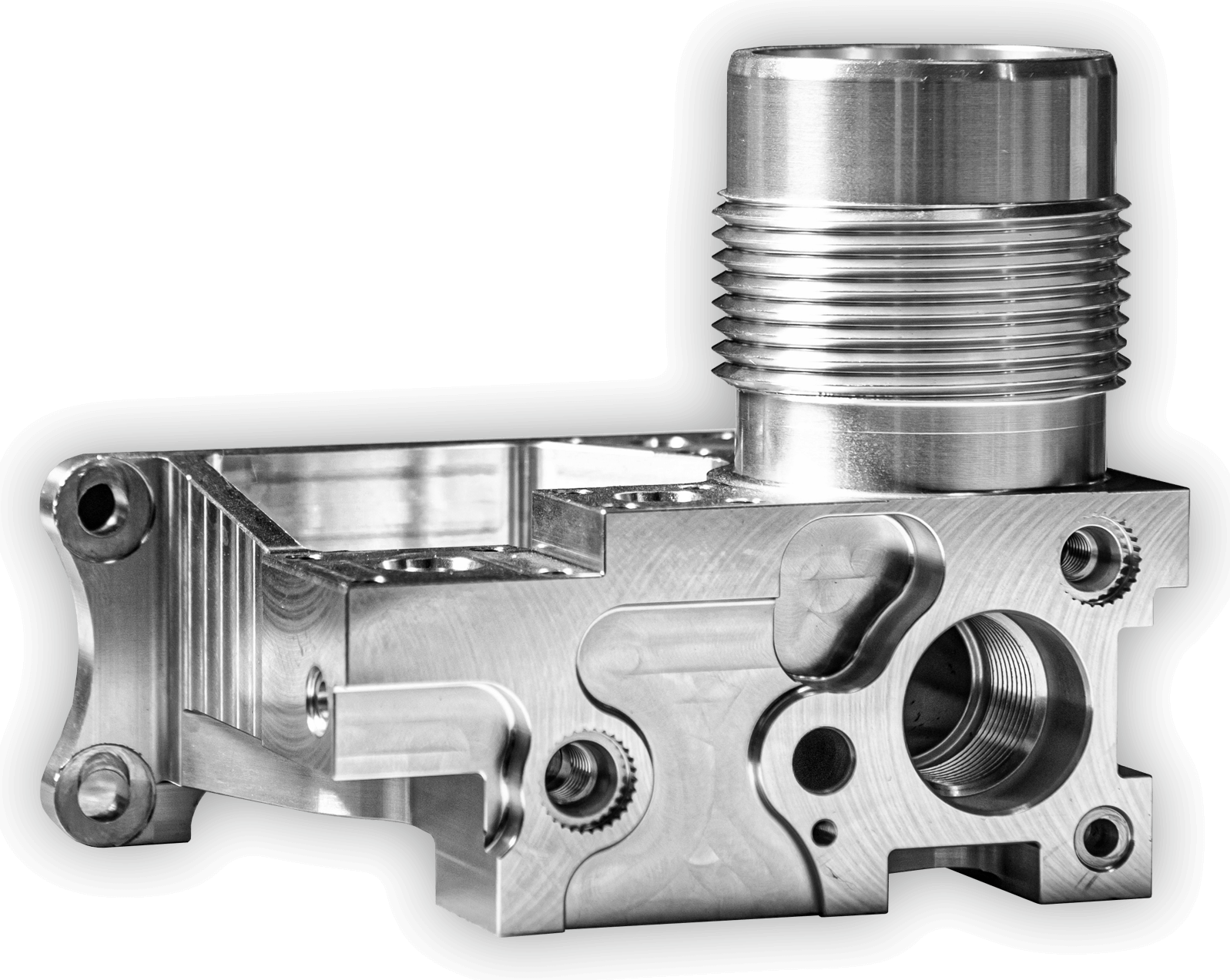

Our CNC turning process produces precision, high-volume components while maintaining quality, efficiency and cost-effective solutions for a wide range of products.

A CAD drawing is first exported into a compatible format and converted into machine instructions using the hyperMILL® CAM software.

The CNC machine needs to be calibrated to ensure that the material is properly aligned and at the correct height before the execution can start.

The CNC machine is then activated and the cutting tool is guided along the programmed path to remove raw material from the component.

Throughout the machining process, sensors and precision measurement tools are used to monitor the dimensions and quality of the part.

At our UK based facility in Reading, we operate 10 CNC turning centres offering a total of 1200 man-hours per week, a capacity of up to 431 x 863mm, a 254mm chuck, and a bar capacity of up to 76mm. With over 70 years of experience, our team of experienced engineers is unrivalled, providing our clients a first-class service from start to finish.

CNC turning is a manufacturing process that involves holding bars of material in a lathe and rotating them while feeding a tool to the piece to remove material (known as subtraction machining) until the desired shape is achieved. This process allows for quick production times at high volumes whilst maintaining the highest quality.

The result is a product engineered with precision and to the highest standards expected by our clients, representing our engineering excellence and first-class service. Each product is quality assured which is certified.

Using state-of-the-art technology and a team of highly skilled engineers, we are proud to produce precision parts for some of the most prestigious businesses in the world.