Our Approach

Our Approach

As a company with a long term proven track record within the aerospace and defence industries we understand what quality means to our customers.

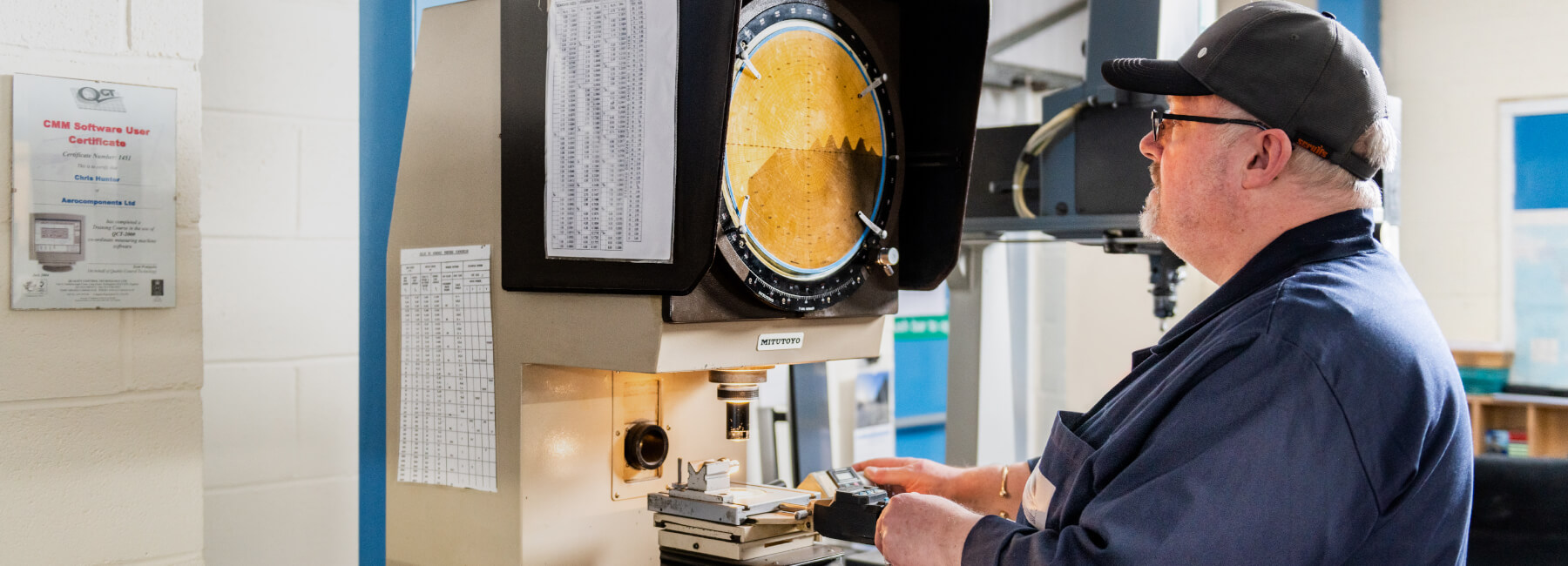

Inspection is a critical part of our service. As well as each machine centre being equipped with online CAD stations and measuring gauges we also operate a dedicated inspection department with two full time quality control engineers. The inspection department is equipped with CMM equipment, profile projectors, toolmakers microscopes, hardness testers and a range of gauges & general measurement equipment.

Depending on the type of contract, most components will pass through the inspection department which is connected to our production management system and CAD/CAM department where they will be inspected and signed for. We offer full certificates of conformity and batch traceability.

This involves measuring the length, width, and height of the component or product using precision measurement tools such as micrometers, calipers, or coordinate measuring machines (CMMs).

This involves measuring the roughness or smoothness of the surface of the component or product using surface roughness testers.

This involves checking that the component or product is manufactured within the specified tolerances for each dimension or feature.

This involves performing various tests on the material used to manufacture the component or product, such as hardness testing or material composition analysis.

One of the most critical components of our production facility are our machines. These are regularly inspected for tool wear as well as bearing and zeroing errors. Because we standardise on the Hurco machine centers we are able to take machines off line for inspection and repair as and when without any loss of production time.