What We Do

What We Do

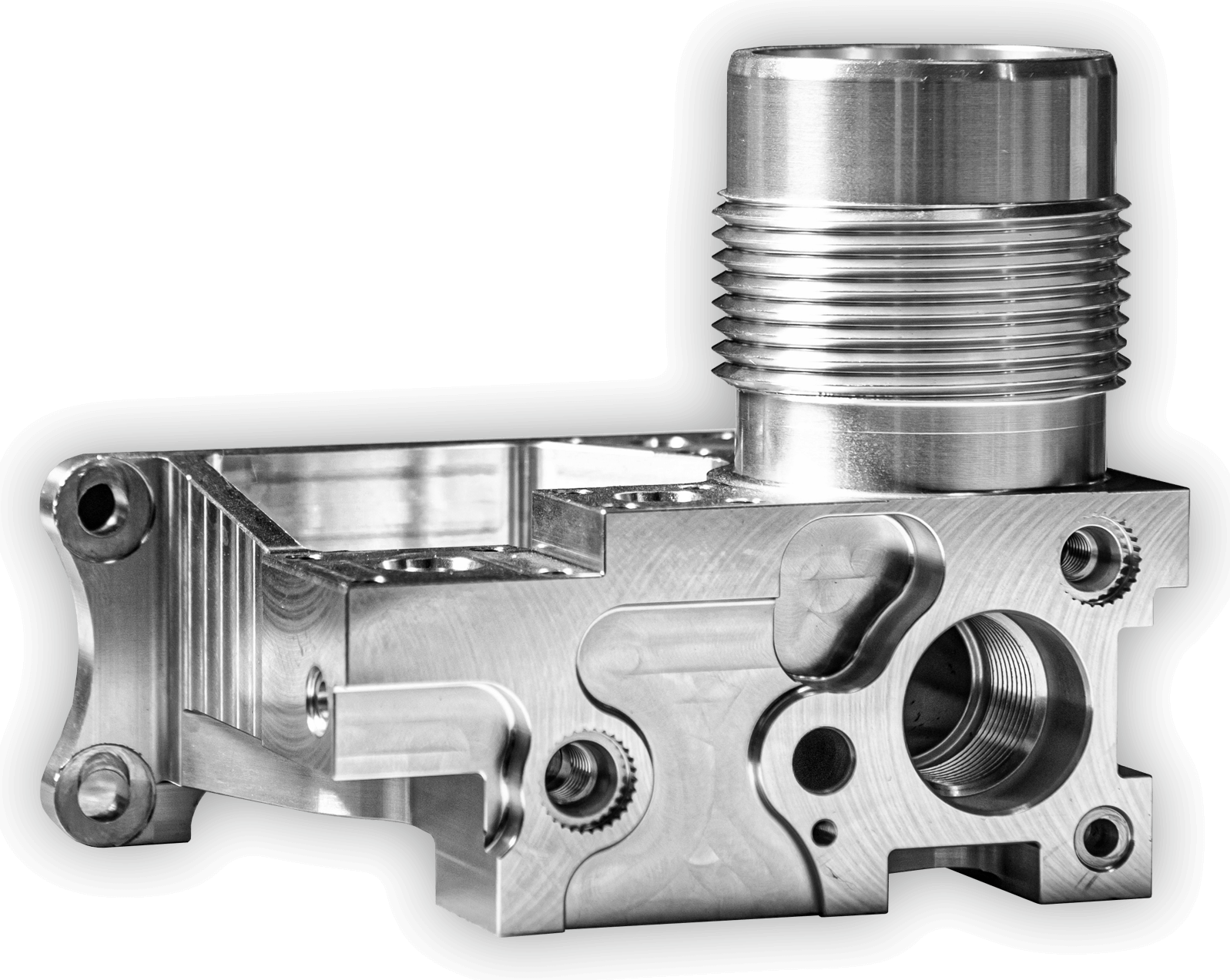

Our CNC milling services offer bespoke, complex components engineered to the highest spec using state-of-the-art Hurco® technology.

A CAD drawing is first exported into a compatible format and converted into machine instructions using the hyperMILL® CAM software.

The CNC machine needs to be calibrated to ensure that the material is properly aligned and at the correct height before the execution can start.

The CNC machine is then activated and the cutting tool is guided along the programmed path to remove raw material from the component.

Throughout the machining process, sensors and precision measurement tools are used to monitor the dimensions and quality of the part.

At our UK based facility in Reading, we operate 18 CNC Hurco® VM1 machining stations which operate 24/7 providing a total of 2160 man hours of CNC Milling capacity per week. With over 70 years of experience, our team of experienced engineers is unrivalled, providing our clients a first-class service from start to finish.

CNC milling is a process that produces custom-designed parts or components by progressively removing material from the workpiece using rotating multi-point cutting tools and computerised controls. These systems generally have three linear degrees of freedom. This restricted dimensional operation reduces the speed of operations, making milling more suitable for prototyping and smaller production runs.

The result is a product engineered with precision and to the highest standards expected by our clients, representing our engineering excellence and first-class service. Each product is quality assured which is certified.

Using state-of-the-art technology and a team of highly skilled engineers, we are proud to produce precision parts for some of the most prestigious businesses in the world.